Welcome to our newsletter. In each edition you can expect to find a wealth of valuable content, including trends shaping the future of our industry, expert opinions from our leading engineers and developers, and exclusive previews of our upcoming projects and product launches.

We hope you find "Impactful Insights" to be an informative and engaging resource. Thank you for being a part of the Impact Electronic Solutions community. Together, we can continue to innovate and lead the way in electronic solutions.

Warm regards,

Beto Dantas, CEO & President

By Jay Schmidt, EVP & General Manager—Vancouver, WA

I am proud to announce Impact ES—Vancouver has received renewed National Aerospace and Defense Contractors Accreditation Program (NADCAP) accreditation for Electronics Printed Board Assemblies, demonstrating our ability to support aerospace companies.

NADCAP is an industry-managed supply chain oversight program that aims to improve quality and reduce costs by assessing process capability for compliance with industry standards and customer requirements. The accreditation is a result of a stringent audit to criteria determined by industry experts, who also evaluate each audit for compliance with those criteria.

While Impact ES-Vancouver is certified to AS9100, which is a set of guidelines governing how companies implement their aerospace quality management system, NADCAP accreditation demonstrates that suppliers meet all the requirements for specific aerospace industry special processes. In our case, this refers to the processes used to manufacture Electronics—Printed Circuit Board Assemblies.

The Chief Operating Officer at the Performance Review Institute stated, "NADCAP accreditation is globally recognized as a hallmark of quality and is a major accomplishment. For many years, the aerospace industry has incorporated NADCAP into its risk management approach, as it demonstrates compliance with industry standards and customer requirements. I am delighted, therefore, that Impact ES has achieved NADCAP accreditation for Electronics—Printed Board Assemblies, and that all their hard work has paid off.”

This achievement underscores the company's commitment to meeting stringent industry standards and maintaining high-quality manufacturing processes.

Congratulations Vancouver Team!

By Nicholas Amore, Electrical Engineer

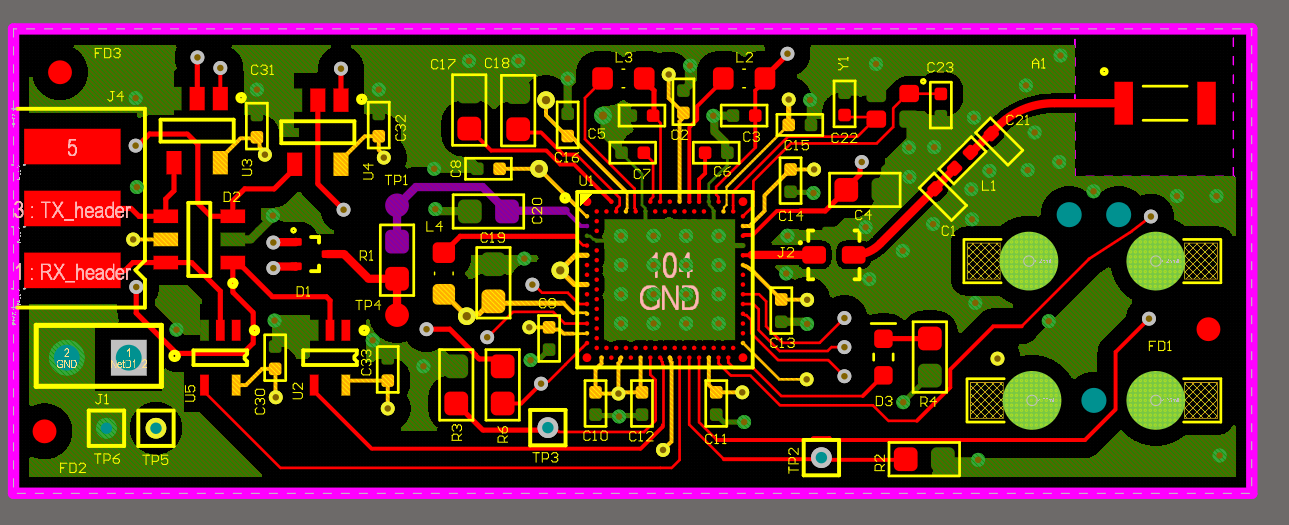

Impact ES has recently shifted from using PADS PCB Design software to Altium Designer for schematic and layout design. While we still support both tools, Altium has become our preferred choice due to its seamless integration of schematic capture and layout design, as well as its overall ease of use. This change has allowed us to streamline the design process, focusing more on implementation rather than overcoming tool limitations. Our team has developed a robust methodology for migrating designs from PADS to Altium, ensuring accuracy and efficiency throughout the process.

The migration process is broken down into carefully reviewed steps to ensure no errors are introduced.

Here’s a detailed look at each phase:

1. BOM Audit and Database Preparation:

Audit the Bill of Materials (BOM) to identify components requiring new entries, symbols, or footprints in the database.

2. Schematic Import and Update:

Import the schematic from PADS.

Update components in the design to their Altium equivalents created during the BOM audit.

Update net names to match the original file set and generate a new netlist.

Compare the generated netlist rigorously against the original to ensure there are no discrepancies.

3. Layout Import and Integration:

Import the layout from PADS and merge it with the schematic updates from the previous step.

Execute design rules and promptly address any residual errors.

4. Output File Generation and Verification:

Generate necessary output files and compare them against the original PADS source files.

Overlay Gerber files from both tools to ensure a 1:1 match.

Evaluate and correct any differences identified in the Gerber file sets as necessary.

By migrating to Altium, Impact ES has enhanced its ability to update designs efficiently. The unified environment of Altium reduces the complexity of design updates, allowing engineers to focus on innovation and implementation rather than troubleshooting tool-related issues. While this migration example specifically addresses PADS, the outlined process is adaptable to any schematic/layout tool, demonstrating our commitment to flexibility and precision in design management.

The switch to Altium Designer has significantly improved the design workflow at Impact ES. Our comprehensive migration process ensures that designs are accurately transferred, maintaining integrity and allowing for seamless updates. This transition underscores our dedication to leveraging advanced tools to deliver high quality engineering solutions.

As part of our newsletter, we want to introduce you to our team, share our Impact culture, values, and how we occasionally have fun at work.

By Lisa Stevenson, HR Manager—Vancouver

The Impact ES—Vancouver site was proud to be a sponsor of the Women in Aerospace Conference last May, which was hosted by the Pacific Northwest Aerospace Alliance (PNAA). The PNAA is a non-profit organization representing a coalition of aerospace companies supporting North America's largest commercial aerospace manufacturing cluster. Jay Schmidt, EVP & General Manager at our Vancouver facility, is a current Board Member for WIA.

The Pacific Northwest has a dynamic aerospace ecosystem, known for over a century of innovation. With over 100,000 individuals employed in the industry and numerous companies advancing aerospace composites, avionics, and alternative fuels, the region is a global leader in aerospace innovation. The conference highlighted the contributions of women in aerospace and emphasized the bright future of the industry, driven by the talented and experienced workforce in the Pacific Northwest.

On March 22nd, the Grants Pass team organized a Guac-Off competition featuring six different guacamole recipes, with three judges from the team. The event was a great way to bring the team together, share ideas, support one another, and enjoy a little friendly competition. In addition to that, the event also provided an opportunity to taste some delicious guacamole.

During the team building Guac-Off, our Manufacturing Supervisor, David Jetmore, emerged the winner with a homemade spicy habanero pepper guacamole. The winner received an at-home guacamole kit and some delicious Takis.

Although the judges found it challenging to pick the best recipe, the habanero guacamole won everyone’s hearts. The organizers expressed their gratitude to everyone who participated and shared their amazing guacamole recipes.

We hope you found this newsletter helpful. Please share it with others and make sure to follow us on LinkedIn for more updates, case studies, and news.