Our agile and customer-centric team assists our customers with the introduction and ongoing support of groundbreaking medical manufacturing products to provide enhanced outcomes for our clients and the well-being of their patients.

Our development process is designed to create devices that meet rigorous approval standards in both the EU and the US. We are also highly adaptable and can easily integrate into your development process. Our agile and customer-centric team facilitates the introduction and ongoing development of groundbreaking medical manufacturing products, driving enhanced outcomes for our clients and improving the well-being of their patients. Choose Impact ES for reliable, innovative solutions in medical fiber optics.

Electronics to Implement Patented Wheelchair Power Assist Technology

Flexible, Wireless Endoscope

Insulin Infusion System

Light Source for a Bone Stabilization System

Mobile Cardiac Monitor

Pocket-Sized Medical Cardiac Monitor

Radiation Therapy Mold Cutter

Sleep Equipment Maintenance Device

Ultrasonic Surgery System

Break-Away Panels

Cellular Modules

Firmware

Graphical Interfaces

CD Screen Designs

PC Applications

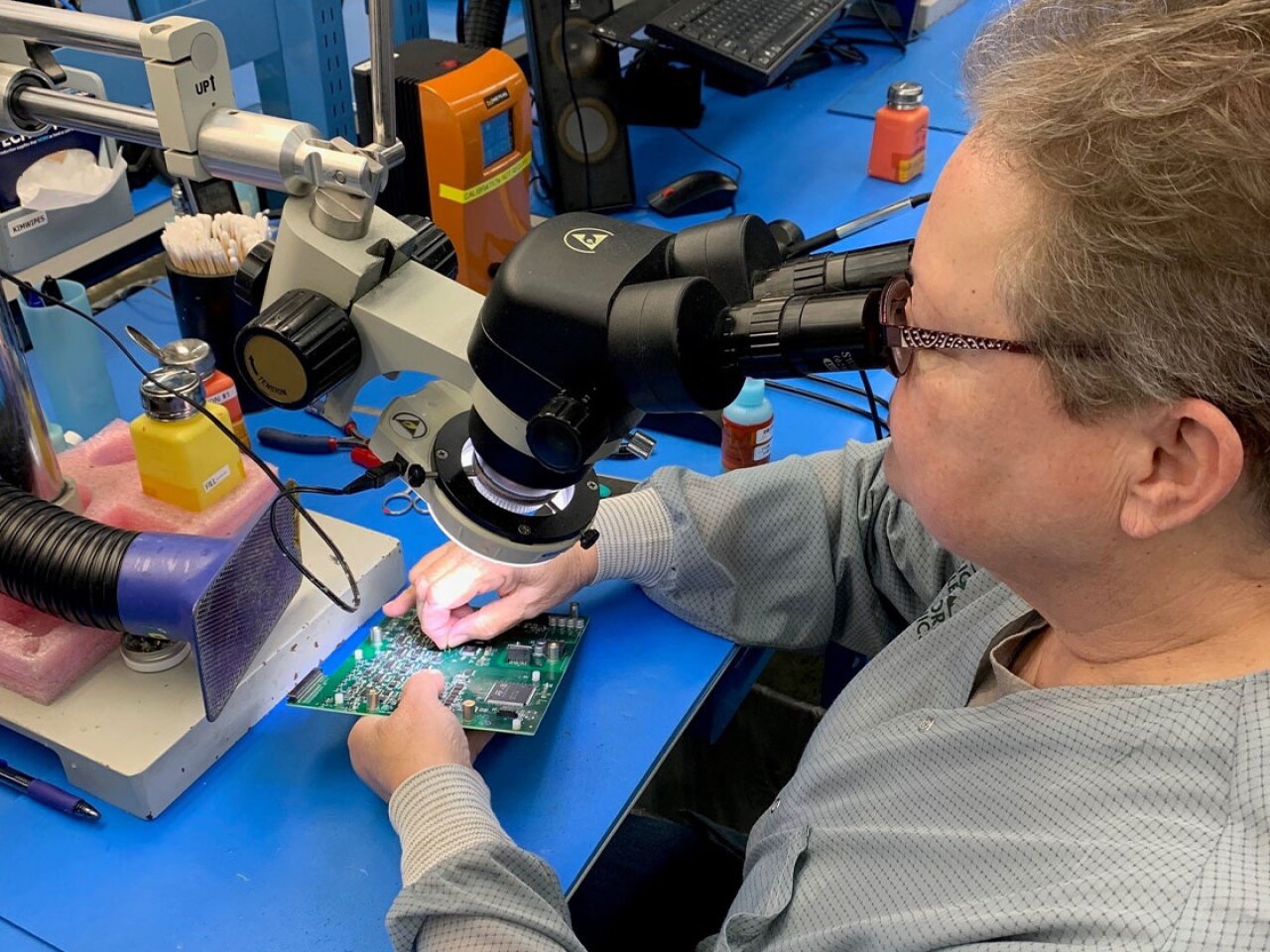

Printed Circuit Boards (PCB)

Software Control Systems

User Interfaces

Windows Simulators (SimGUI) for Remote Controllers

Flow cytometry cables

Blood diagnostic cables

Cancer detection cables

Arterial catheter fibers

High power laser fibers

All product development begins with the creation of a requirements document based on your user needs and exhaustive research.

Our review-based process ensures all our designs are reliable, accurate, flexible, and meet the highest quality standards.

Our nimble, customer-focused team introduces and sustains innovative products that provide better outcomes for our customers and their patients.

Proficient in the implementation of medical risk management processes, we collaborate with you to develop your product documentation.

Beyond delivering exceptional technical expertise, we foster strong collaborative relationships with expert design firms and manufacturing groups.

We provide weekly status reports to help keep projects running smoothly to meet and exceed your expectations.