We have extensive experience supporting universities, government research labs, and corporate R&D centers by providing the materials they need to advance their research and development.

We maintain an inventory of hundreds of connectors, fibers, and cabling options, enabling us to rapidly build highly customized assemblies to meet your exact specifications. Additionally, we have comprehensive testing capabilities for loss, back reflection, polarization extinction ratio, beam profile, connector end-face profiles, fiber eccentricity, and optical path lengths.

Matched Optical Path Length Cables and Devices

Specialty fibers pulled up to 100 meters though plastic or steel cabling

Connectors have survived 150 watts continuous power and 2,000-watt pulses

LIDAR Assemblies

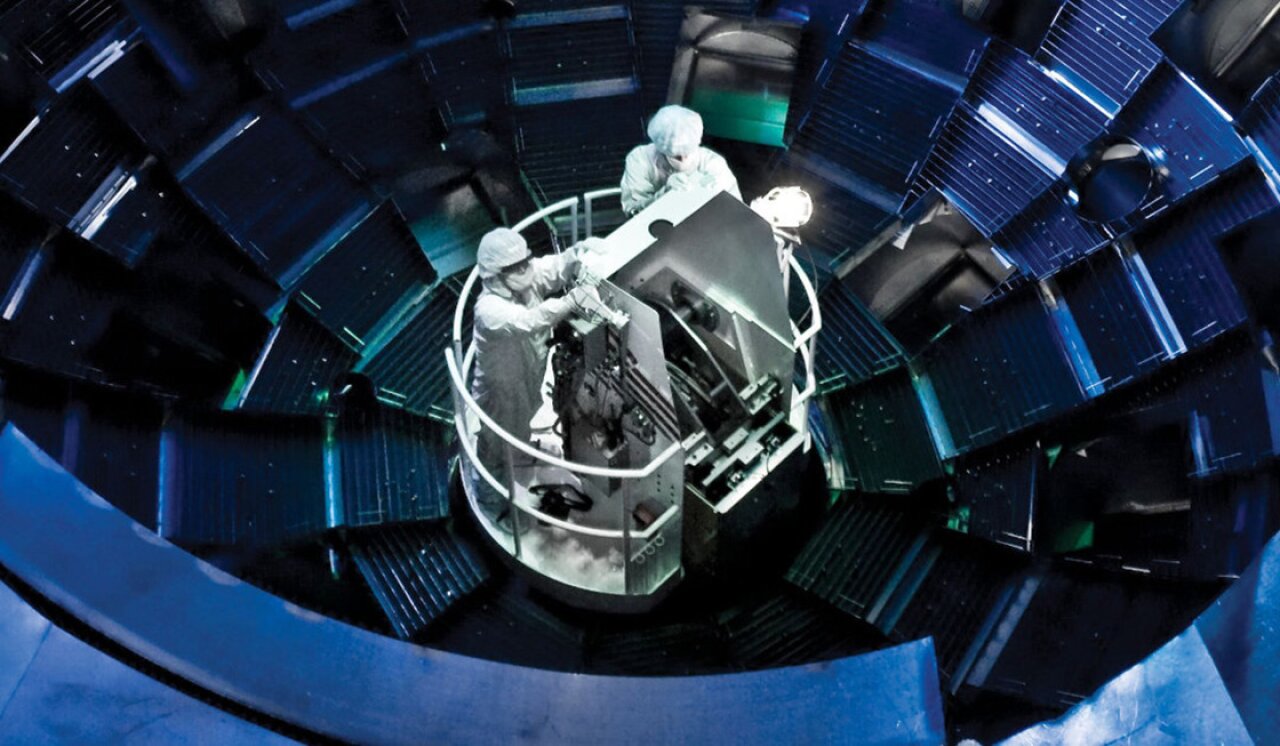

Nuclear fusion support

Quantum Computer cables

Atom splitting support

Explosives development using PVDF probes

Climate change studies with LiDAR

SETI (Search for Extra Terrestrial Intelligence) Support

All product development begins with the creation of a requirements document based on your user needs and exhaustive research.

We consistently invest in our people, engineering resources, and equipment to stay on the leading edge of the technologies our customers are invested in.

Instead of simply assembling products from point A to point B, our engineers collaborate with customers to offer innovative and custom solutions.

Our well-defined test strategy allows our customers to capitalize on their return on investment and reduce their test-related costs.

We provide weekly status reports to help us keep projects running smoothly and help us meet and exceed your expectations.

Our quality system is the result of more than 25 years of advancement and development of best practices, processes, and tools.